As in the current market scenario many enterprises indeed face the challenge of balancing productivity and profitability just because of “many styles and small quantities,” The CNC Knife cutting system is a viable solution for batch production.

The batch production is crucial as it reduces inventory costs and optimizes space utilization. When receiving orders of different quantities, enterprises can make flexible choices between automated continuous production and quantitative manual layout processing. This adaptability allows companies to respond efficiently to diverse order sizes and production demands.

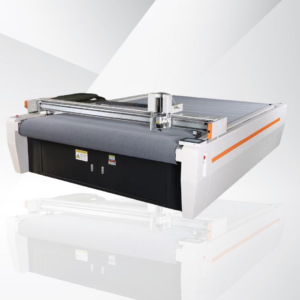

The CCD camera tracking positioning, hanging large visual projection system, automatic feeding table, and the multiple-operation head are the key components which works together to truly provide intelligent cutting solutions for companies of various sizes.

The CCD camera tracking positioning ensures accurate cutting by precisely locating the material, reducing errors and waste. The hanging large visual projection system offers a clear view of the cutting process, facilitating monitoring and quality control.

The automatic feeding table enables smooth material handling, enhancing workflow efficiency. The multiple-operation head provides increased productivity by allowing simultaneous cutting operations, reducing production time.

Overall, this integrated system offers a comprehensive and intelligent approach to leather cutting, enabling enterprises to meet the challenges of the modern market while optimizing productivity and profitability.

Video

Advantages

1. The cutting graphic image projected through the projector which reflects the layout position of the graphic in real time, and the layout is efficient and fast, saving time, effort and materials.

2. The multi heads cut the material at the same time which increases the efficiency & meet the production goals of small batches, multiple orders and multiple styles.

3. It can be used for cutting genuine leather and other flexible materials. Widely used in the shoemaking industry, luggage industry, decoration industry, etc.

4. The cutting machine equipped with programmable multi-axis motion controller system and advance transmission system adopts imported linear guides, racks, and synchronous belts, which helps to achieve the cutting accuracy.

5. User friendly high-definition touch screen human-machine interface, convenient operation, simple and easy to learn. Standard RJ45 network data transmission, fast speed, stable and reliable transmission.