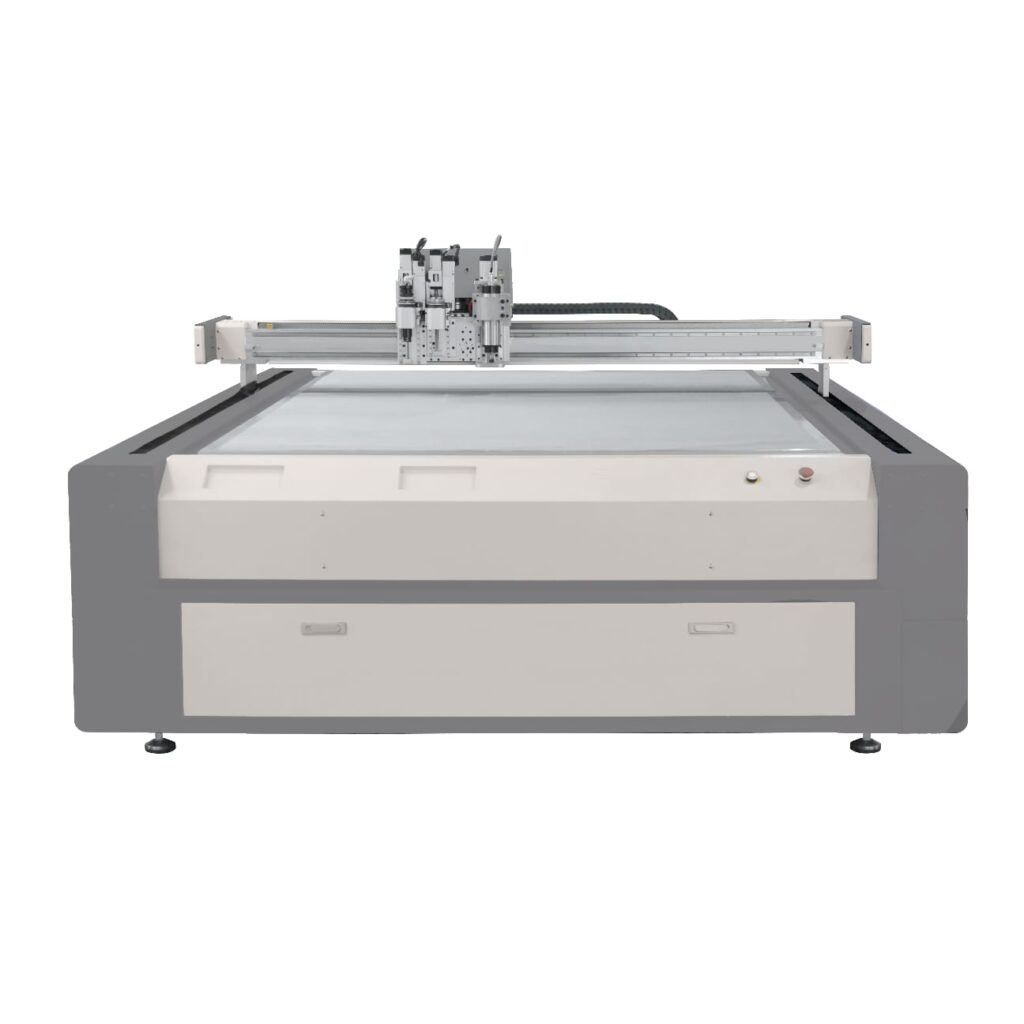

The Flexocut Digital Cutting Machine is a state-of-the-art intelligent solution specifically designed for proofing and small-batch customized production in the packaging and printing industries. Built to meet the dynamic needs of modern packaging, it delivers unmatched precision, speed, and flexibility.The Flexocut machine enables businesses to produce precise, creative, and high-quality packaging products faster and more conveniently. It is perfectly suited for fulfilling today’s growing demand for customized packaging solutions that help brands differentiate in a crowded marketplace.

With its intelligent features and multifunctional design, the Flexocut Digital Cutting Machine is transforming the packaging and printing industries—driving innovation, efficiency, and competitiveness for forward-thinking manufacturers.

Video

Advantages

1. One machine has multiple functions, batch processing of different materials, short orders, fast response, and fast delivery.

2. Reduce labor, one worker can operate multiple devices at the same time, equipped with typesetting and imposition functions, improving efficiency and achieving significant cost optimization results.

3. One person can operate multiple devices at the same time, equipped with typesetting and imposition functions, and the cost optimization results are significant.

4. Computer numerical control, automatic cutting, 7-inch LCD industrial touch screen, standard Dongling servo;

5. High-speed spindle motor, the speed can reach 18,000 revolutions per minute;

6. Any point positioning, cutting (vibrating knife, pneumatic knife, round knife, etc.), half-cutting (basic function), indentation, V-groove, automatic feeding, CCD positioning, pen writing (optional function);

7. High-precision Taiwan Hiwin linear guide rail, with Taiwan TBI screw as the core machine base, to ensure accuracy and precision;

8. Cutting blade material is tungsten steel from Japan

9. Regin high-pressure vacuum pump, to ensure accurate positioning by adsorption

10. The only one in the industry to use host computer cutting software, easy to install and simple to operate.

Reviews

There are no reviews yet.