The leather digital cutter machine is not only used to cut leather, but it can also be used to cut the extensive application in non-metallic materials with a thickness not exceeding 60mm. The machine can be customizing to cut the higher thickness materials up to 10cm.

This includes a diverse range of materials such as genuine leather, composite materials, corrugated paper, car mats, car interiors, cartons, color boxes, soft PVC crystal pads, composite sealing materials, soles, rubber, cardboard, gray board, KT board, pearl cotton, sponge, and plush toys, etc.

Video

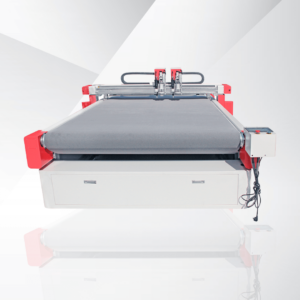

Advantages

1. The machine equipped with the scanning-layout-cutting system.

2. It can be used for continuous cutting which saves manpower, time and materials loses.

3. Dual gantry, dual heads system which works synchronously. This will double the efficiency & production quantity.

4. Automatic layout of irregular materials.

5. Improve material utilization, cutting accuracy, cutting speed.

6. Smart computerized numerical control, fully automatic cutting, 7-inch LCD industrial touch screen, high-end servo drives and motors.