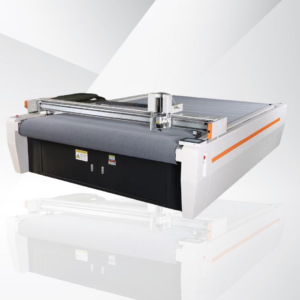

Flexocut’s insulation cotton and acoustic panel cutting machine is a versatile and high-performance solution designed to meet the diverse processing needs of the sound insulation industry. It efficiently handles a wide range of materials, including sound insulation boards, insulation cotton, and various insulation panels, supporting both personalized customization and large-scale production.

Digital cutting machine engineered for speed and precision, Flexocut enables manufacturers to deliver high-quality products faster and more accurately, even in limited time and space. This flexibility empowers businesses to meet complex customer demands while maintaining top-tier quality standards.

Flexocut provides advanced cutting solutions that boost user competitiveness and support sustainable industry growth. It’s not just a machine—it’s a strategic tool for promoting efficiency, innovation, and long-term success in the acoustic and insulation manufacturing sectors.

Video

Advantages

1. CNC automatic cutting, 7-inch LCD industrial touch screen, standard servo system.

2. High-end servo drives, high speed spindle servo motor, the speed can reach 18,000 revolutions per minute.

3. Any point positioning, with multiple options and choices for cutting tools.

4. High-precision Taiwan make Hi-win linear guide rail, with Taiwan TBI screw as the core machine base, to ensure accuracy and precision.

5. Cutting blade made of tungsten steel material

6. Negative high-pressure vacuum pump is used to ensure accurate positioning by adsorption

7. Host computer cutting software, easy to install and simple to operate.