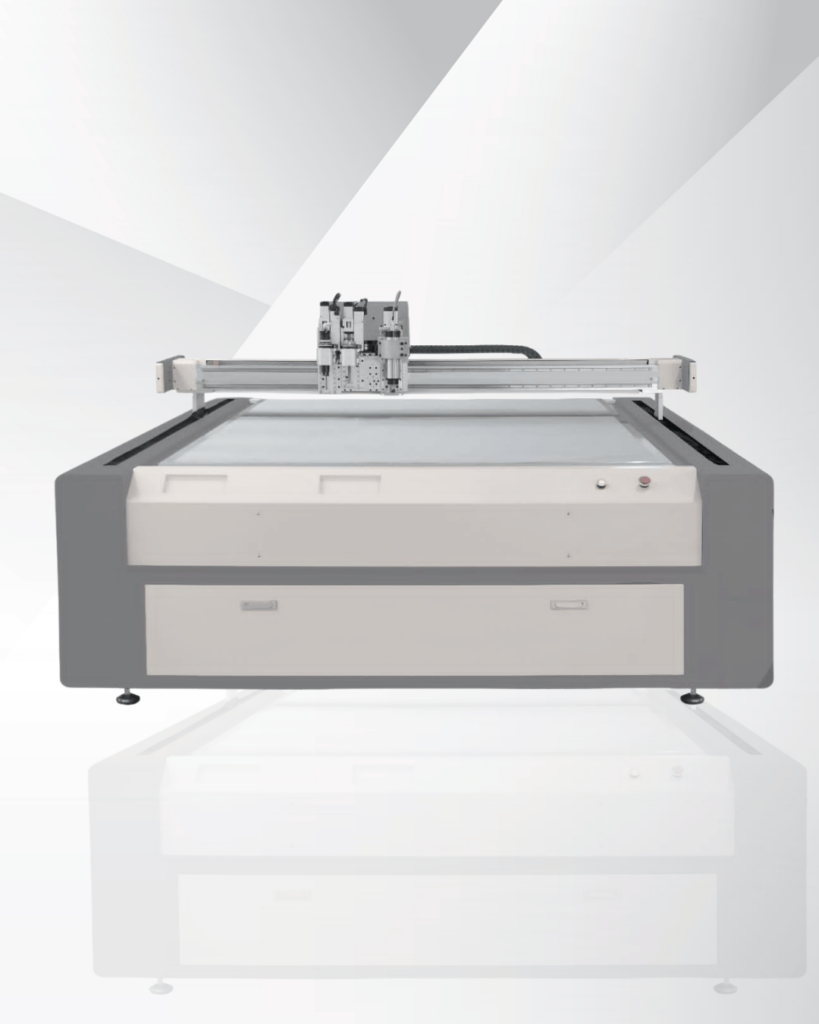

CNC Knife cutting machine is a highly advanced and versatile solution designed to meet the demanding needs of the soft furnishing industry. It supports a wide range of materials including leather, genuine leather, and various types of fabrics.

These automated machines are equipped with an intelligent nesting system, automatic cutting, and user-friendly features like one-key size change, automatic error compensation, and automatic marking, the machine streamlines operations while ensuring exceptional precision.

It reduces dependability on manual work and delivers significant cost savings and boosts production efficiency. The multi-functional tool exchange system—featuring vibration knife, circular knife, marker pen, and punching tools—enables multiple processes to be performed on a single machine.

These digital cutters are known for its stable performance and high cutting accuracy, Flexocut helps manufacturers achieve consistent quality, increase productivity, and reduce labor costs—making it an essential asset for modern home furnishing production.

Video

Advantages

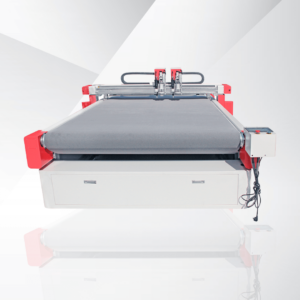

1. One machine has multiple functions, batch processing of different materials, short orders, fast response, and fast delivery.

2. It reduces labor & labor cost, one worker can operate multiple devices at the same time, which is equipped with nesting and imposition functions, improving efficiency and achieving significant cost optimization results.

3. Smart computerized numerical control, fully automatic cutting, 7-inch LCD industrial touch screen, high-end servo drives.

4. High-speed servo motors, the speed can reach 18,000 revolutions per minute.

5. Any point positioning, multiple cutting tools configurations.

6. High-precision linear guide rails, rack, reducers, synchronize belt & ball screw to ensure accuracy and precision.

7. Cutting blade material is tungsten steel from Japan

8. Branded high-pressure vacuum pump, to ensure accurate positioning by adsorption

9. Smart & intelligent host computer cutting software, easy to install and simple to operate.