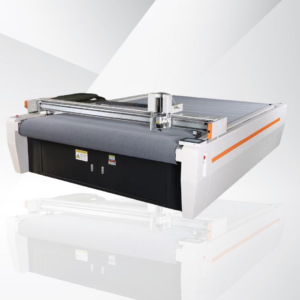

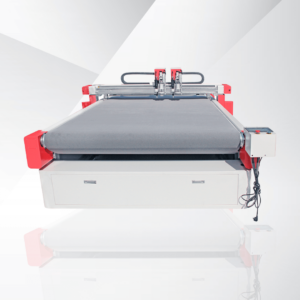

The gasket digital cutting machine is a CNC vibration knife cutting machine that can be widely used not only to cut gasket related materials such as sealing ring gaskets, rubber, silicone, graphite, graphite composite gaskets, asbestos, asbestos-free materials. But it can also be used to cut other materials like cork, PTFE, leather, composite materials, corrugated paper, car mats, car interiors, cartons, color boxes, soft PVC crystal pads, composite sealing ring materials, soles, cardboard, gray board, KT board, pearl cotton, sponge, and plush toys, etc.

The gasket cutting machine is built to achieve high precision and high speed, and high accuracy. It can cut any design and special-shaped gasket seals. The finished work piece has no saw tooth, no burrs, and no burns. It looks very smooth & accurate cutting.

Video

Advantages

1. No need of expensive molds and dies for cutting.

2. Intelligent layout system, smart nesting option for maximum material utilization.

3. Taiwan make guide rail transmission system with highest accuracy of ±0.02mm

4. High-speed servo drives and motors, production efficiency increased by more than four times

5. Easy Interchangeable tools, easy cutting of different material types, thicknesses and shapes.

6. User friendly operation, easy to operate.

7. The blades made of tungsten steel material which supports to cut graphite metal gasket

8. Smooth cutting edge, no burrs, and no burns. Precise & accurate cutting results.