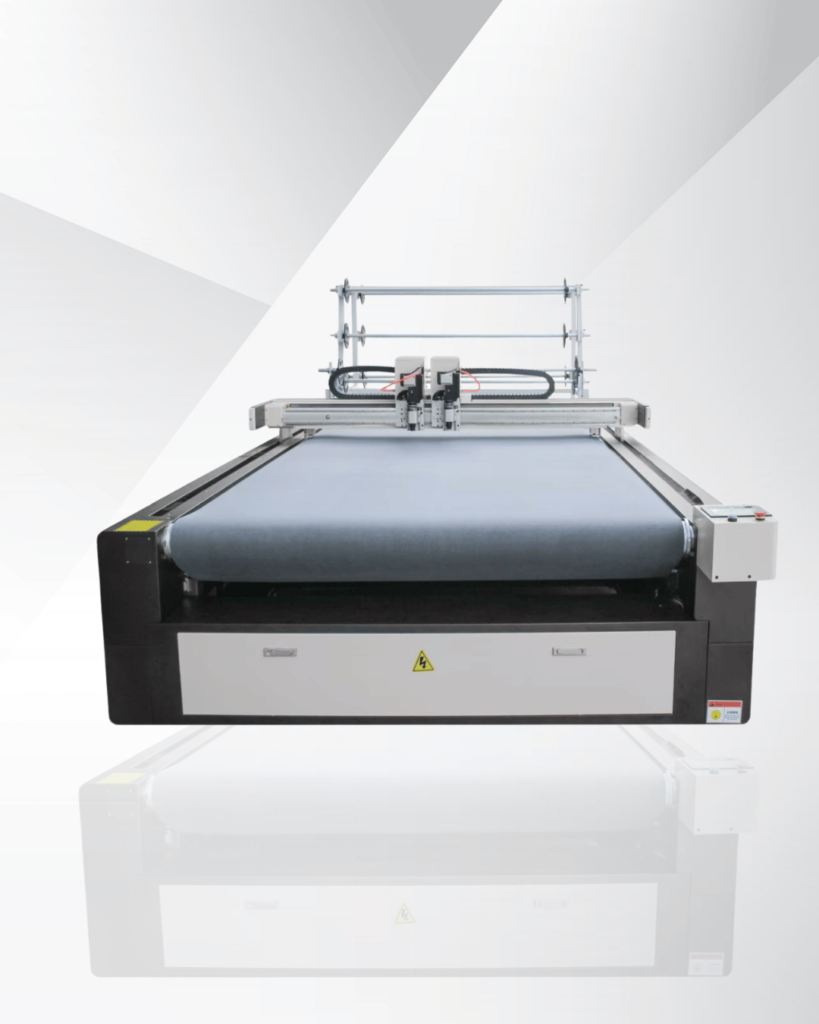

The Garment Fabric digital cutting machine is a kind of CNC special-shaped cutting machine. The equipment is widely used to cut non-metallic flexible materials. The maximum thickness of material should not exceeding 6cm; The machine beam height can be customized according to material thickness & user needs.

The CNC Knife cutting machines are more suitable for clothing cutting, proofing, edge finding and cutting of printed fabrics, silicone cloth, non-woven fabrics, plastic-coated fabrics, Oxford cloth, balloon silk, felt, functional textiles, molding materials, fabric banners, PVC banner materials, mats, synthetic fibers, raincoat fabrics, carpets, carbon fibers, glass fibers, aramid fibers, prepreg materials, etc.

The machine is equipped with automatic coil pulling, loading and unloading system. Tungsten blades are used for smooth cutting, the cutting results are smokeless and odorless, and there will be no lint, saw tooth and burns.

CNC cutting machines provides professional solutions for proofing and small batch production in the textile and garment industry. Garment Fabric cutting machine is equipped with high-speed active wheel cutter, electric vibration cutter, gas vibration cutter and third-generation punching head (optional). Whether you need to cut chiffon, silk, wool or denim, can provide suitable cutting tools and solutions for different types of cutting rooms such as men’s wear, women’s wear, children’s wear, fur, women’s underwear, sportswear, etc.

Video

Advantages

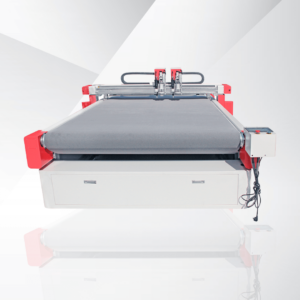

1. The machine equipped with the scanning-layout-cutting system.

2. It can be used for continuous cutting which saves manpower, time and materials loses.

3. Dual gantry, dual heads system which works synchronously. This will double the efficiency & production quantity.

4. Automatic layout of irregular materials.

5. Improve material utilization, cutting accuracy, cutting speed.

6. Smart computerized numerical control, fully automatic cutting, 7-inch LCD industrial touch screen, high-end servo drives and motors.