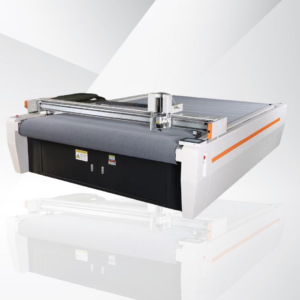

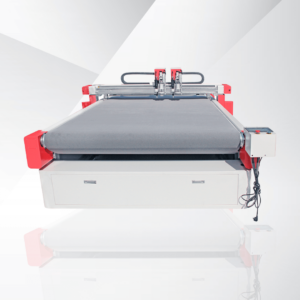

| Machine Model |

FCT-1625 (Optional)

|

| Material feeding system |

Automatic feeding felt bed / Fixed felt bed (Both options available)

|

| Effective cutting area (LxW) |

2500 x1600mm

|

| Overall size (LxWxH) |

3571 x 2504 x 1325mm

|

| Special size |

Customizable (On demand)

|

| Multi-function machine head |

Multi knife head holders, tool quick-insert fixing, convenient and fast replacement of cutting tools, plug and play, integrating cutting, milling, slotting, punching, marking and other functions (Options available)

|

| Cutting tool configuration |

vibration knife, drag knife, half knife, drawing pen, cursor, pneumatic knife, flying knife, pressure wheel, V-groove knife, electric vibration cutting tool, flying knife tool, milling tool, drag knife tool, slotting tool, etc.

|

| Cutting materials |

Carbon fiber/prepreg, TPU/base film, carbon fiber cured board, glass fiber prepreg/dry cloth, epoxy resin board, polyester fiber sound-absorbing board, PE film/adhesive film, film/net cloth, glass fiber/XPE, graphite/asbestos/rubber, etc.

|

| Cutting speed |

≤1500mm/s (actual speed depends on the material, thickness, and the cutting pattern)

|

| Cutting thickness |

0.2-60mm (customizable height)

|

| Cutting accuracy |

±0.1mm

|

| Repeat accuracy |

≦0.05mm

|

| Cutting circle diameter |

≧2mm diameter

|

| Positioning method |

laser light positioning, CCD, and the large visual positioning

|

| Material fixing method |

vacuum adsorption, optional intelligent multi-zone vacuum adsorption and follow-up adsorption

|

| Safety device |

physical anti-collision mechanism + infrared induction anti-collision to ensure production safety + Infrared sensing, sensitive response, safe and reliable

|

| Intereface |

USB / Ethernet port

|

| Compatible software format |

AI software, AutoCAD, Corel DRAW and all box design software can be directly output without conversion, and with automatic optimization

|

| Data format |

PDF, DXF, HPGL, PLT, etc. compatible format

|

| Operation panel |

multi-language LCD touch panel

|

| Transmission system |

Advance servo system, high-precision linear guide, precision gear rack, synchronous belts, lead screws, high-performance servo motor and driver

|

| Servo resuolution |

±0.01mm

|

| X, Y axis motor and driver |

X axis 400w, Y1Y2 axis 400w HCFA / DELTA / PANASONIC (Options available)

|

| Z, W axis motor driver |

Z axis 100w, W axis 100w HCFA / DELTA / PANASONIC (Options available)

|

| Lubrication system |

Automatic lubrication system for X/Y/Z Rail guide & Gear

|

| Air pump power |

7.5KW

|

| Power supply voltage |

AC 220V 380V ±10%, 50HZ; whole machine power 11kw; fuse specification 6A

|

| Working environment |

temperature: -10℃~40℃, humidity: 20%~80%RH

|