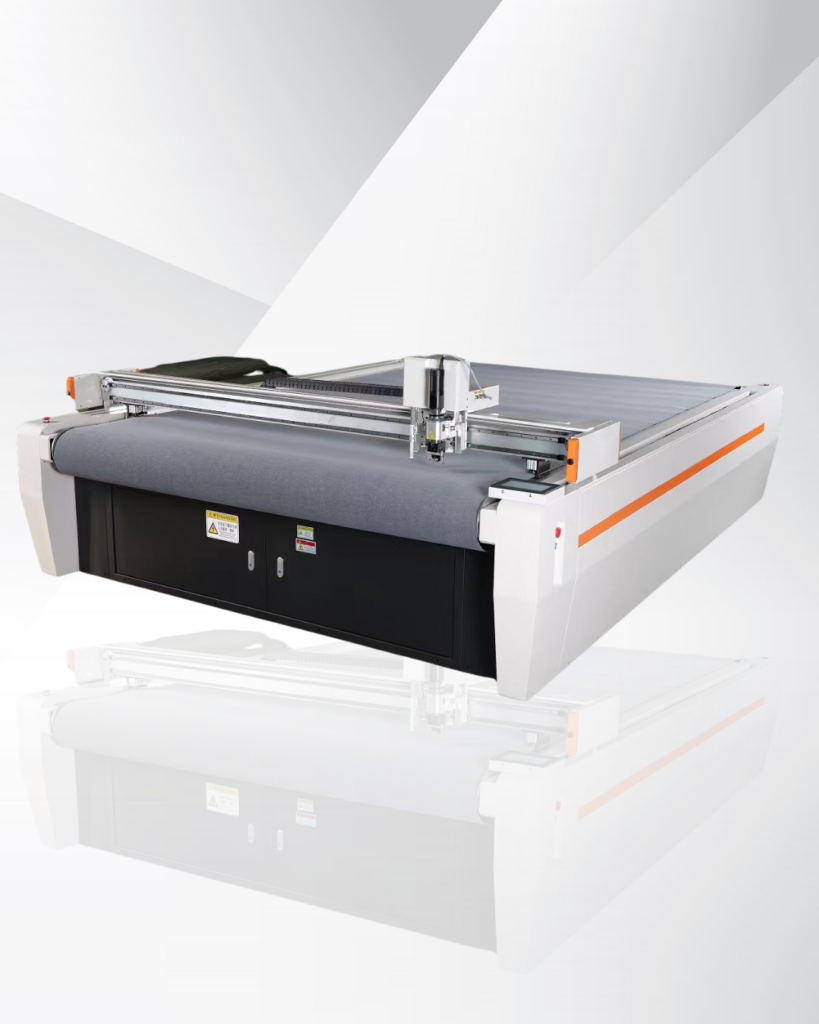

The Flexocut Composite material cutting Machine is a state-of-the-art vibration knife cutting system; it is specially designed for processing non-metallic materials up to 6cm thickness. It offers exceptional versatility, making it more ideal for a wide range of industries and applications.

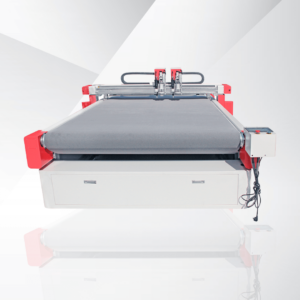

The machine built in such a way that it can integrates multiple knives and pens, allowing it to meet various cutting and drawing needs with high-speed, high-precision, and smart automation.

This cutting solution enables businesses to seamlessly transition from manual to advanced production modes, significantly increasing efficiency, reducing labor intensity & cost, and ensuring superior cutting accuracy. It’s the more economical, cost effective and the perfect tool for customization, on-demand production, delivering the flexibility and precision required for today’s composite material industries.

Video

Advantages

1. Integrated solution of line drawing, design drawing, text marking, indentation, half-knife cutting, and full-knife cutting. All functions work together and increase the work efficiency.

2. Comes with automatic feeding conveyor belt for continuous cutting and seamless docking. This Meet the production goals of small batches, multiple orders, and multiple design styles.

3. Programmable multi-axis motion controller, stability and operability reach the leading technical level. The cutting machine transmission system adopts imported linear guides, racks, and synchronous belts to achieve the cutting accuracy & repeatability.

4. User friendly high-definition touch screen human-machine interface, convenient operation, simple and easy to learn and operate.