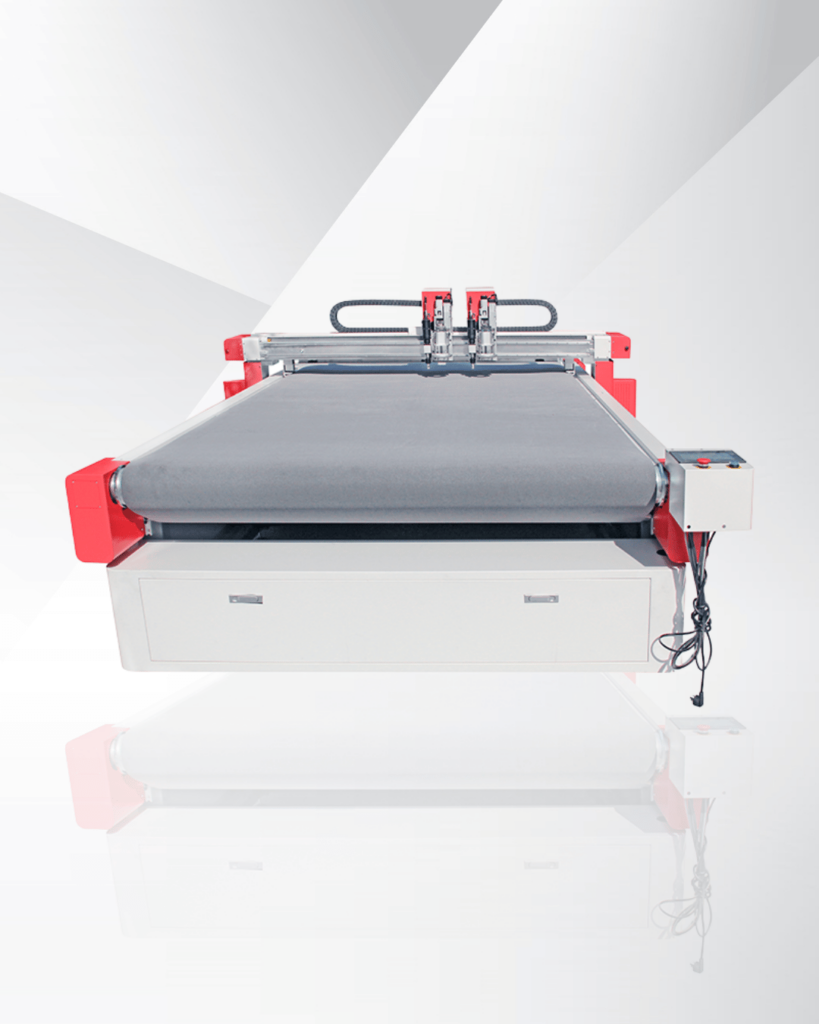

The Flexocut’s carpet cutting machine is designed to bring revolution in the carpet manufacturing and processing industry with its smart automation and precision engineering.

This equipment is manufactured to handle special-shaped carpets and printed designs; this eliminates the need for traditional templates methods. One-click intelligent edge detection and cutting make the process faster, easier, and far more efficient.

Knife cutting technology engineered for performance, precision, and sustainability, the Flexocut carpet cutting machine is an essential tool for modern carpet manufacturers seeking to improve efficiency, reduce waste, and stay competitive in a fast-evolving market.

Video

Advantages

1. Computer numerical control, automatic cutting, 7-inch LCD industrial touch screen, standard motion system.

2. High-end servo drives and speed spindle motors, the speed can reach 18,000 revolutions per minute.

3. It is equip with fully automatic feeding system for continuous production. The system has multiple cutting tool options. It is easy for quick change overs.

4. High-precision linear guide rail, rack, belts and reducers are used to ensure accuracy and precision.

5. Specially designed tungsten material cutting blades which can cover all your cutting needs.

6. Quality negative high pressure vacuum pump is used, to ensure accurate positioning by adsorption.