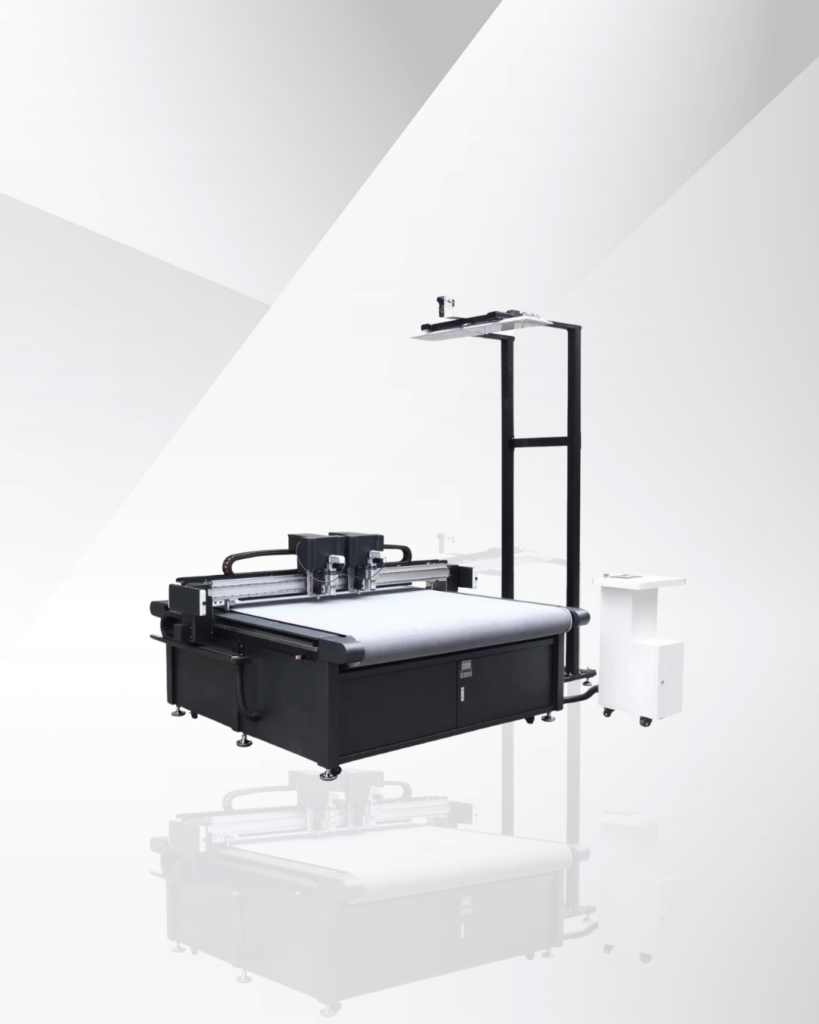

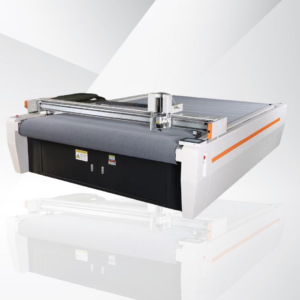

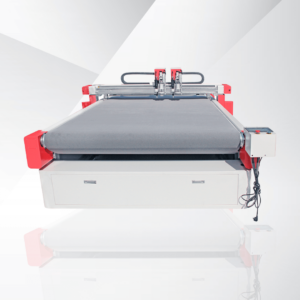

Car interior digital cutting machine is designed for high-precision cutting of non-metallic materials up to 6cm thickness, making it ideal for a wide range of automotive and industrial applications. It can cut variety of material including car mats, sound-absorbing cotton, leather, composite materials, corrugated paper, cartons, color boxes, soft PVC crystal pads, sealing ring composites, rubber, gray board, KT board, pearl cotton, sponge, plush fabrics, and more.

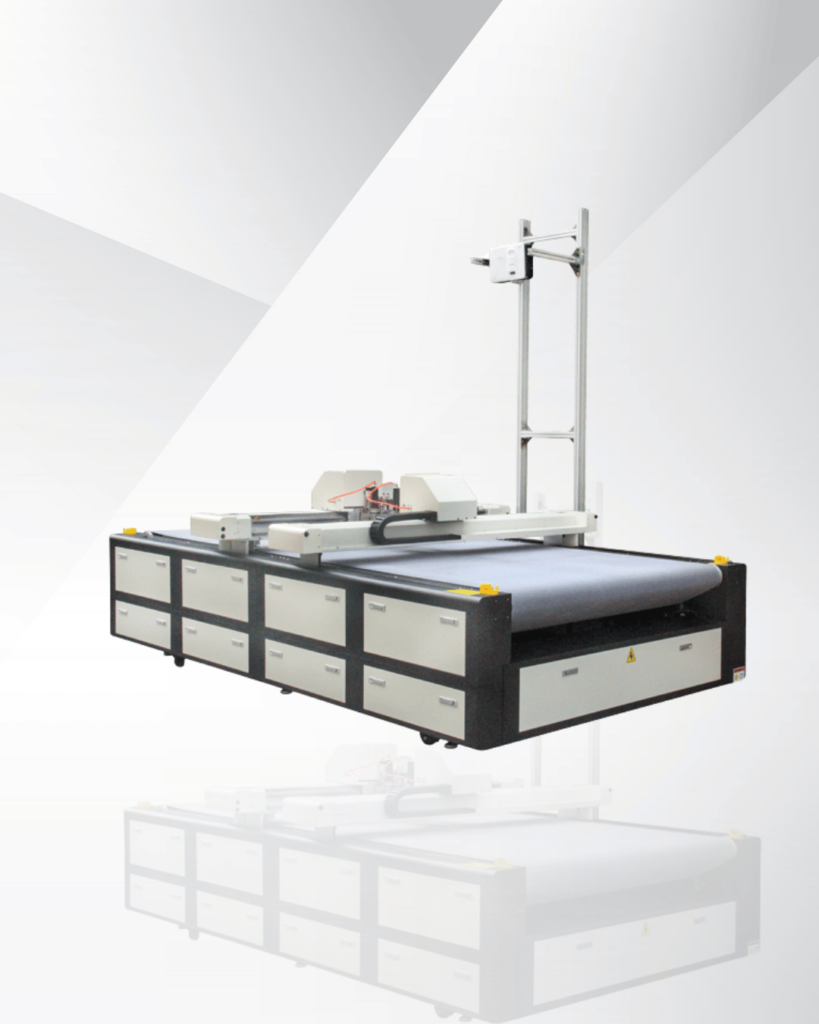

It is equipped with fully automatic feeding conveyor belt system and an optional fixed table cutting system, this machine is perfectly suited for producing items like foot mats, seat covers, cushions, light-shielding pads, leather seats, and car covers with high speed and accuracy.

Flexocut’s digital cutting machines empowers manufacturers with a flexible, automated cutting solution built for performance, precision, and production scalability in the automotive interior sector.

Video

Advantages

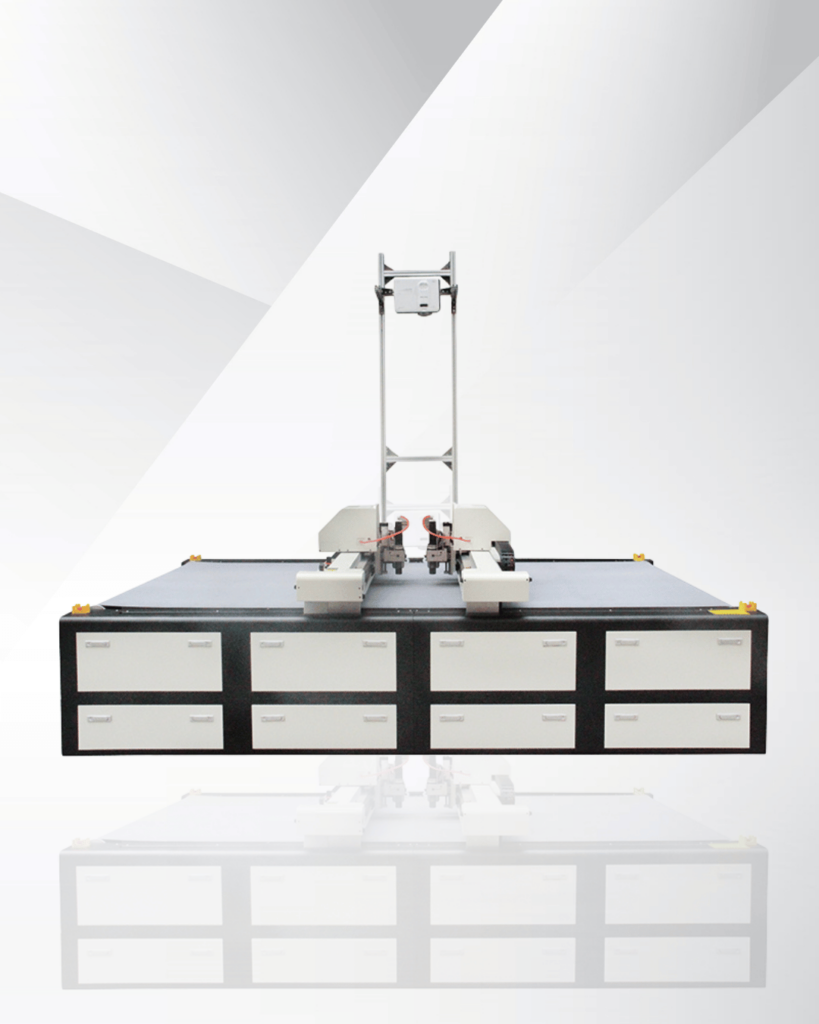

1. The system is equipped with multiple features like line drawing, pattern drawing, text marking, indentation, half-knife cutting, full-knife cutting, all this is done at a time.

2. The Fully automatic feeding conveyor belt ensures continuous cutting and seamless docking.

3. Meet the production goals of small batches, multiple orders, multiple styles, and designs.

4. CNC Programmable multi-axis motion controller, stability and operability reach the leading technical level.

5. The cutting machine transmission system adopts imported linear guides, racks, and synchronous belts ensure the best cutting accuracy and repeatability.

6. User friendly high-definition touch screen human-machine interface, convenient operation, simple and easy to operate.